Umbhobho weNtsimbi oManzi eludongeni

Imveliso kunye nenkqubo yokuvelisa umbhobho wensimbi ongenamthungo onzima unokwahlulwa ube ngumzobo obandayo, ukuqengqeleka okubandayo, ukuqengqeleka okushushu kunye nokwandiswa okushushu.Izinto zombhobho wensimbi ziyi-10, 20, 35 kunye ne-45, ezibizwa ngokuba yipayipi yensimbi eqhelekileyo.Ngokwesicelo, inokwahlulwa ibe ngumbhobho wentsimbi, umbhobho wentsimbi ongenamthungo wothutho, umbhobho wentsimbi ongenamthungo kwibhoyila, umbhobho wentsimbi ongenamthungo woxinzelelo oluphezulu, umbhobho wentsimbi ongenamthungo wezixhobo zesichumiso sekhemikhali kunye nentsimbi engenamthungo. iGeological Drilling Umbhobho;umbhobho wentsimbi ongenamthungo wokugrumba ioli;umbhobho wentsimbi ongenamthungo wokuqhekeka kwepetroleum;umbhobho wentsimbi ongenamthungo wenqanawa;umbhobho wentsimbi ongenamthungo otsaliweyo kwaye obandayo oqengqelekayo;imibhobho ye-alloy eyahlukeneyo.Umbhobho wensimbi ongenamthungo usetyenziswa ikakhulu kumatshini wokucutshungulwa, umgodi wamalahle, intsimbi yehydraulic, njl.

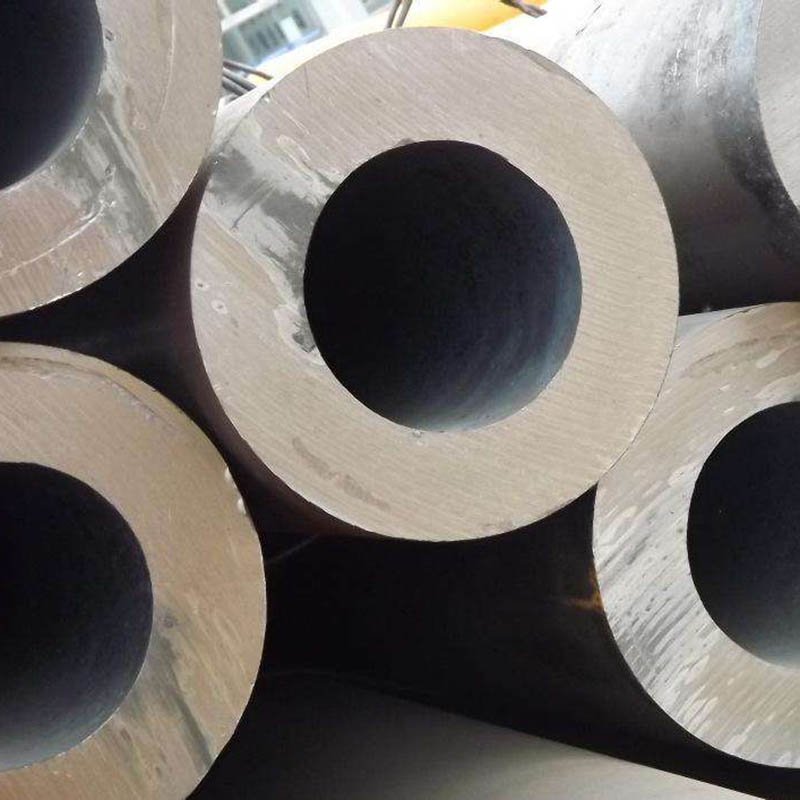

Imathiriyeli ekrwada yodonga olungqingqwa lombhobho wentsimbi engenamthungo yityhubhu engqukuva engenanto.Umbhobho ojikelezayo ongenanto unqunywe ngumatshini wokusika, kwaye i-billet ngokukhula malunga ne-1 m ithunyelwa esithandweni somlilo ngebhanti yokuhambisa ukufudumeza.Ibillet ifudunyezwa kwiziko elimalunga ne-1200 degrees Celsius.Amafutha yihydrogen okanye iacetylene.Ukulawulwa kweqondo lokushisa kwisithando somlilo kuyingxaki ephambili.Emva kokuba ityhubhu ejikelezayo ikhutshwe kwisithando somlilo, kufuneka idlule kwi-piercer pressure.Ngokubanzi, oyena mgqobhozi uxhaphakileyo ngumgqobhozo we-cone roll.Olu hlobo lokugqobhoza lunemveliso ephezulu, umgangatho olungileyo wemveliso, ukwandiswa kwedayamitha yokugqobhoza okukhulu, kwaye unokunxiba amabakala amaninzi entsimbi.Emva kokubhoboza, i-billet ejikelezileyo iqhutywe ngokulandelelana ngokugqithwa kwe-roll cross rolling, i-rolling eqhubekayo okanye i-extrusion.Emva kwe-extrusion, ityhubhu kufuneka isuswe ukulinganisa.Umatshini wokulinganisa ujikelezisa i-cone drill bit kwintsimbi engenanto ngesantya esiphezulu ukwenza umbhobho wentsimbi.

Ububanzi bangaphakathi bombhobho wensimbi buchongwa ngubude obungaphandle bobubanzi be-drill bit yomatshini wokulinganisa.Emva kokulinganisa, umbhobho wensimbi ungena kwinqaba yokupholisa kwaye upholiswe ngokutshiza kwamanzi.Emva kokupholisa, umbhobho wensimbi uya kulungiswa.Emva kokulungiswa, umbhobho wensimbi uthunyelwa kwi-metal flaw detector (okanye uvavanyo lwe-hydraulic) ngebhanti yokuhambisa ukukhangela impazamo yangaphakathi.Ukuba kukho iintanda kunye namaqamza ngaphakathi kumbhobho wentsimbi, iya kufunyanwa.Emva kokuhlolwa komgangatho wemibhobho yentsimbi, ukhetho olungqongqo lwencwadi luyafuneka.Emva kokuhlolwa komgangatho wombhobho wensimbi, inombolo, inkcazo kunye nenani lebhetshi yokuvelisa iya kutshizwa ngepeyinti.Inyuselwa kwindawo yokugcina impahla ngecrane.

UMbhobho wentsimbi ONGAMTHUNGO OLUNDONDA

Nxiba ukumelana nokuzithambisa Ukuthambisa okuphezulu kweekhemikhali Ubukhulu obahlukeneyo kunye nohlobo

Imveliso kunye nenkqubo yokuvelisa umbhobho wensimbi ongenamthungo onzima unokwahlulwa ube ngumzobo obandayo, ukuqengqeleka okubandayo, ukuqengqeleka okushushu kunye nokwandiswa okushushu.

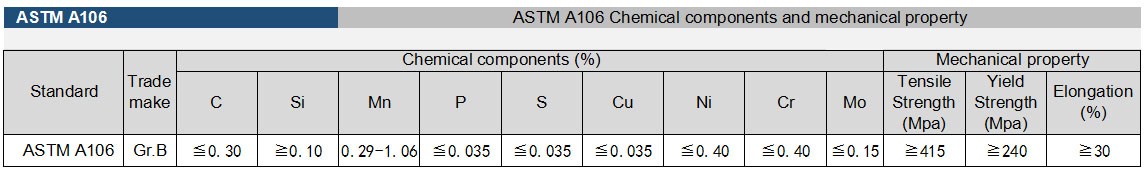

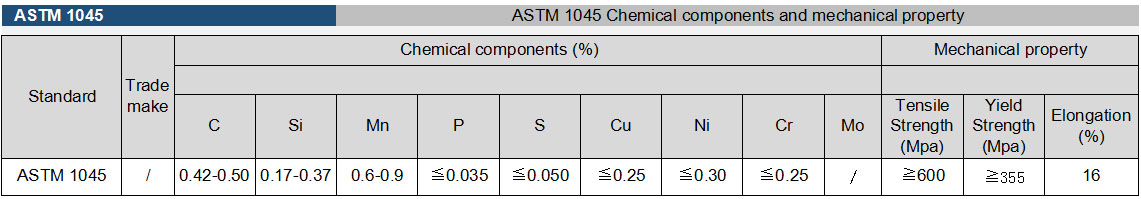

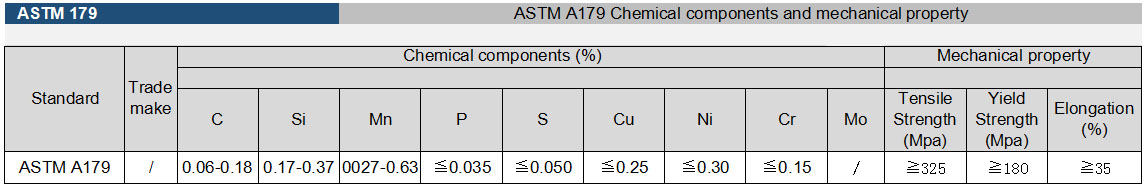

Izinto zombhobho wensimbi ziyi-ASTM 179, i-A106Gr.B, i-1035 kunye ne-1045, ebizwa ngokuba yipayipi ye-carbon steel eqhelekileyo.

Izinto zombhobho wensimbi ziyi-ST52, i-ASTM 5140,4140,4135,12XMФ, ebizwa ngokuba yipayipi yensimbi eqhelekileyo.

I-ASTM A106Gr.B ukwakheka kweekhemikhali kunye neempawu zomatshini

I-ASTM 1045 yokwakheka kweekhemikhali kunye neempawu zoomatshini

Ukwakheka kweekhemikhali ze-ASTM A179 kunye neempawu zoomatshini

Ubukhulu obufanayo

I-ALLOY EMBHAYIBHILE ONGENSIMENE OMTHUNGO